Back to top

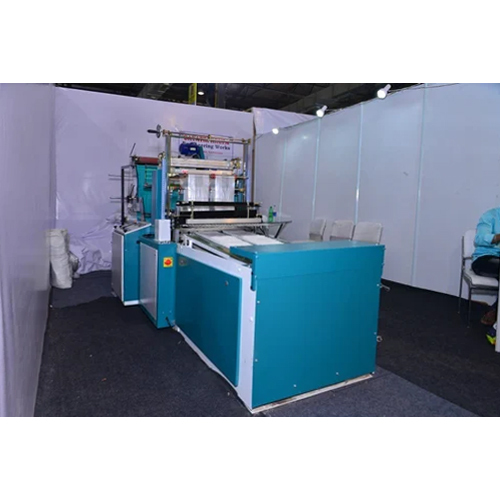

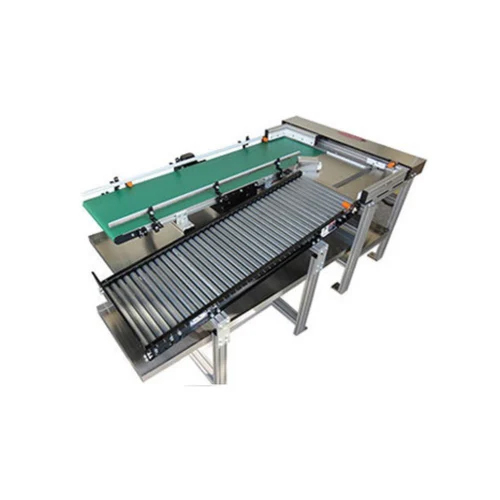

Precision Built for Performance Double Decker Bag Machines, Compostable Bag Makers, and Belt Conveyor Systems You Can Trust.

Gayatrikrupa Engineering Works is devoted to providing the latest solutions for plastic bag production and material handling equipment. The company, in its capacity as a manufacturer and supplier, aims to have a single-minded drive, to engineer machines that reimagine operational effectiveness and revolutionize production capabilities. Based on a reputation of innovation and credibility, the business addresses diverse industry requirements with entirely automated solutions designed to reduce labor costs, minimize energy consumption, and deliver predictable, high-value output.

Range from the

double decker bottom seal bag-creating machine to automated belt

conveyor systems, each piece of equipment demonstrates an intimate

know-how of customers' needs as well as an awareness of where the

industry is headed. These machines are endowed with sophisticated

sealing technology, intelligent fault detection, added edge protection,

and a wide range of acceptance for different types of film as well as

formats of bags. Be it a compostable bag-making machine, plastic tote

bag machine for industries, or bottom sealer cutting machine, there's

always a watchword that says precision, speed, and environmental

friendliness. Offering whisper-quiet operation, quick size changes, and

upgrade-future-proofed module-based designs, the technology is easily

integrated into existing lines and makes monitoring a breeze. Usability

merges with innovation through simple touchscreen interfaces,

personalized settings, and quick warm-up features, allowing production

lines to operate with minimum downtime.

Our Infrastructure

A solid infrastructure underpins all the manufacturing operations. With the R&D housing advanced, quality testing labs, and a full-scale production facility, the space is optimized for operational fluency. Smart layouts and cutting-edge machinery facilitate seamless workflows through procurement, packaging, and dispatch. This arrangement enables the engineering team to design machines with strong construction, high-speed outputs, and robust tension management. Every unit is a product of engineering delicacy supported by technological prowess, providing machines that not only work but deliver in challenging industrial environments. With the customer at our heart, we keep on manufacturing machines that drive industries ahead, dependably, intelligently, and efficiently.

Our Infrastructure

A solid infrastructure underpins all the manufacturing operations. With the R&D housing advanced, quality testing labs, and a full-scale production facility, the space is optimized for operational fluency. Smart layouts and cutting-edge machinery facilitate seamless workflows through procurement, packaging, and dispatch. This arrangement enables the engineering team to design machines with strong construction, high-speed outputs, and robust tension management. Every unit is a product of engineering delicacy supported by technological prowess, providing machines that not only work but deliver in challenging industrial environments. With the customer at our heart, we keep on manufacturing machines that drive industries ahead, dependably, intelligently, and efficiently.

Send Inquiry

Send Inquiry Send SMS

Send SMS